Check out our

Google Reviews!

Need to hire a forklift truck in London?

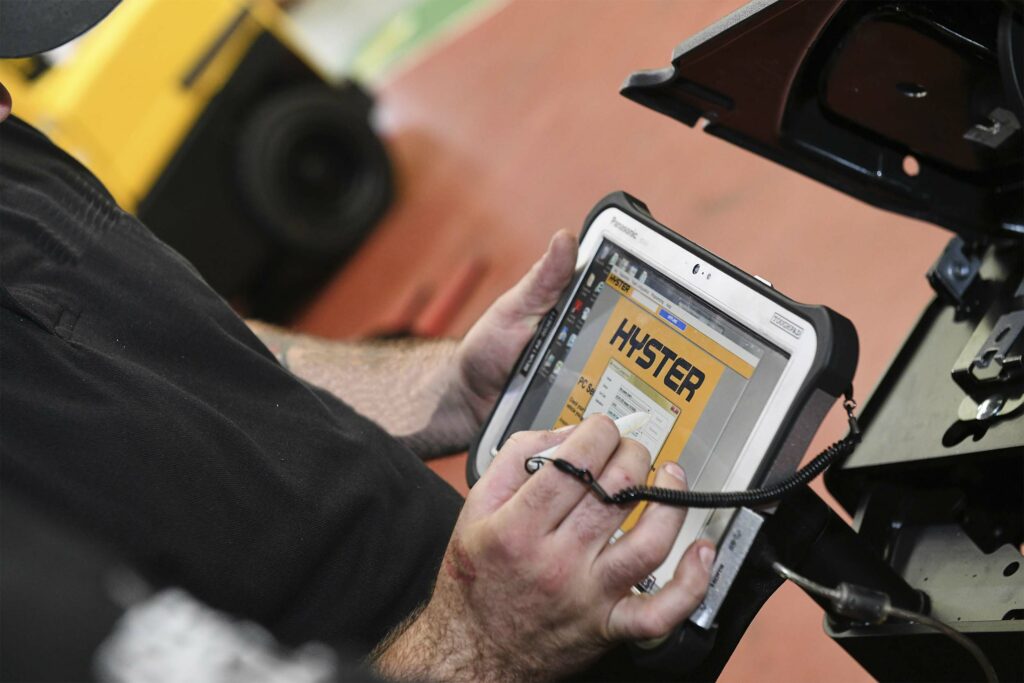

You’ve found the right place. We are the exclusive dealer for the Hyster range of forklift trucks in London, and we pride ourselves in offering the best one-stop shop materials handling solutions.

| Our clients include well-known household names to single users. We look after our customers, which is why we are the number-one forklift truck company in London. There’s a reason we have been in business for over 25 years. |  |

- Are looking to hire a forklift in London on a short or long-term basis?

- Are you looking to buy a new or used lift truck?

- Are you looking for driver training?

- Has your forklift broken down and need repairing?

If the answer is yes to any of the above then we’d love to hear from you. We’ve been providing materials handling solutions to businesses in London and the South East for 25 years, and we understand the fast-paced nature of businesses in London which is why your truck will be delivered on time.

Latest from our blog

8 Reasons why your business could benefit from latest Hyster lithium-ion forklifts

London’s number one forklift supplier Hiremech can find you the...

Hiremech seal another deal with long-term partner DCL

When Designated Contractors Ltd (DCL) required four Hyster...

Wholegood upgrades warehouse efficiency with Hiremech’s refurbished Hyster Reach Truck

Hiremech have supplied a fully refurbished Hyster Reach Truck...

We plant a tree for every truck we sell

Why should you use us to hire or buy a forklift?

Our range

We offer the biggest range of forklifts for sale in London – gas, diesel or electric powered to suit your needs.

Logistics

We’re used to working to tough schedules, and can offer solutions to any job.

Availability

We are renowned for our stock of trucks – whenever you need one it’s here for you.

Our clients

People who have used us before love us! Reliable, well-priced and friendly – guaranteed.

Our location

We are handily located for pick-up in Tottenham, north London, and can deliver trucks anywhere they are needed.

We are a leading force in the forklift industry

We work with all sizes of company

Don’t accept second best. We have been a leading force in the London forklift industry for 20 years and the quality of our service and attention to detail reflects this.

We have more than 1000 forklift trucks out on hire at any given time and a range of quality used equipment, all of which are of an exceptional standard and quality. We also have a range of pallet trucks, electric pallet trucks as well as various maintenance packages to get you and your business moving.

If you’re looking to hire a truck for a day or on a long-term contract then get in touch and we will give you a price today. Whatever your requirement, contact us now on 020 8880 3322, or fill in the web-form below with your details and we will call you back.

We work with all sizes of company

We have been in London for more than 20 years, and in that time have worked with hundreds of different companies.

From TfL to the store round the corner, we keep London working.

‘Quality of work, efficiency, excellent ethos and competitive rates is why we always choose Hiremech’

London Underground

Quick links

Hire

Sales

Servicing

Training

Clients

020 8880 3322

020 8880 3322